For better or worse, most of the gasoline you can buy at stations around the U.S. has been “oxygenated” with some kind of additive since a series of amendments were made to the Clean Air Act in the 1990s. The idea is to help the gasoline burn more completely, and thus cut down on harmful emissions. The latest additive is ethanol, which — without getting into the political and environmental debates about its efficacy — is fine for use in fuel-injected vehicles that are run regularly and designed to use up to 10% ethanol (85% in flex-fuel vehicles).

On the other hand, ethanol-oxygenated fuel is not so great for any vehicles that sit between uses, and/or carbureted engines, like the one in your dirt bike or older motorcycle. Ethanol is alcohol, and alcohol is corrosive to certain parts in older fuel systems. Alcohol is also “hygroscopic” and likes water, so when water gets into fuel during a fill-up or from condensation, it can mix with the ethanol, creating a chemical combo that causes rust, corrosion, acids and sticky varnish that wreak havoc in fuel systems, especially carburetors. Ethanol can even cause rubber parts and fuel lines to dry out, harden and deteriorate prematurely.

Alternatives are few — unless you’re lucky enough to have a fuel supplier or gas station near you that sells ethanol-free gasoline (see pure-gas.com or buyrealgas.com), or you’re OK paying $15-$18 per gallon for ethanol-free gas in cans from a dealer (see vpracingfuels.com), most of us are stuck buying gasoline oxygenated with 10% ethanol. Again, your modern fuel-injected vehicle that you store in a dry place and run at least twice a month is unlikely to suffer any ill effects, but what should someone do with their older carbureted bike (or boat, lawnmower, string trimmer, generator, etc.)?

The simplest, best advice I can offer is…don’t let them sit. The shelf life of unstabilized gasoline containing ethanol is about one month. Running your vehicles every week — or two maximum — until fully warm is the best way to prevent fuel delivery problems. When you can’t run them, here’s what I do to minimize (not eliminate!) problems with my small collection of bikes, and my generator, string trimmer and lawnmower, even spare fuel in cans.

Half Full, Half Empty

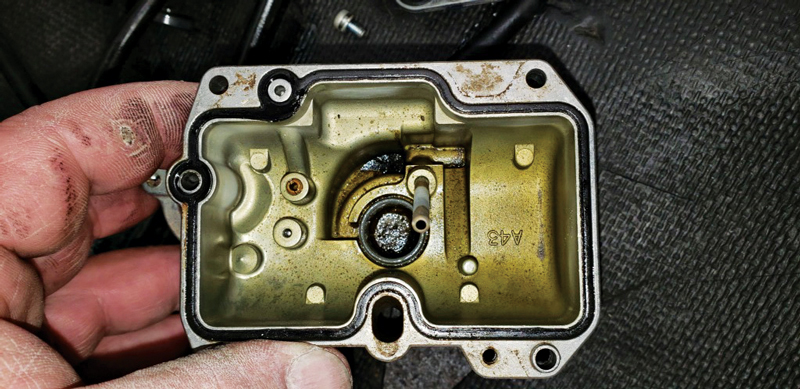

On carbureted bikes with steel gas tanks, half the fuel system should be drained, and the other half kept full. Carburetors and their tiny air passages and jets can become plugged with aged fuel that deteriorates into sticky varnish over time. Since carb internals are made of non-ferrous aluminum, brass, plastic and rubber that won’t rust, if it’s practical to drain them (shut off the gas manually first or look for a vacuum-operated-type petcock that is off whenever the bike is), this is your best bet for trouble-free operation when refilled. O-rings and seals have been known to dry out and leak when carbs are left dry for a very long time, but this is less likely than plugged jets or worse if they’re left wet.

Some carburetors have a drain bolt in the bottom of their float bowls, others have a drain screw. Don’t overtighten either one, and only drain carburetors (into something please, not just onto the bike and floor) when the bike is off and cold. Don’t run the bike until it dies to suck the rest out — this can draw dirt and debris from the bottom of the float bowl into the carburetor. I once bought a Honda multi that had been stored in a basement for 15 years with the carbs drained and stabilized fuel kept in the tank, and it was rust-free and fired right up without carb service. If you’re careful, there’s no reason you can’t return newer, clean drained fuel to the tank.

Steel tanks on carbureted or fuel-injected bikes can rust inside, so it’s best to leave them at least ¾ full of fuel to which you have added stabilizer (more on this later). Some newer models have plastic-shrouded aluminum or plastic tanks, in which case it’s up to you, but make sure you stabilize it if you leave fuel in the tank. In really humid environments I would still keep an aluminum tank full.

Fuel injection systems seem much less susceptible to the ravages of stale fuel, and once full of stabilized fuel are almost carefree. In fact, some manufacturers warn against running their EFI bikes entirely out of fuel.

If you can’t drain carbs, after adding stabilizer to the fuel in the tank run the bike long enough to insure stabilized fuel has filled them, then shut off the bike and petcock. I carry a small bottle of stabilizer with me when I take out one of my less frequently ridden bikes, and add it at the gas station before riding home. Err on the side of adding more stabilizer; you can’t overdose (within reason) with the products mentioned below. Stabilized fuel in the carbs does not guarantee that they won’t suffer from plugged passages or jets, however, and you should still run bikes kept this way at least every three weeks. More often is simple insurance that you won’t need an expensive service — compare the cost of non-ethanol race gas and/or stabilizer to that of a carburetor rebuild and the former start to make economic sense. Just make sure you run the engine until it’s fully warm (to burn off water and contaminants in the oil and exhaust). While you’re at it, pump the fork and shocks and work the brakes, clutch and shifter to keep seals flexible and lubricated.

A Stable Relationship

A good ally in the fight against bad gas and fuel delivery issues is fuel stabilizer. They’re not foolproof, but three we’ve found to provide consistent results with motorcycles are Star Tron Enzyme Fuel Treatment, Spectro FC Premium Fuel Conditioner & Stabilizer and Bel Ray All-in-One Fuel Treatment. There are others, but we lean toward these simply because they include motorcycles in their literature and FAQs and that gives us a warm, fuzzy feeling. All make lots of claims about their effectiveness that we have no way of proving or disproving, so just buy some and use it, or spend hours online researching them before you just buy some and use it. All of them offer smaller bottles and/or containers with measuring devices built-in to make carrying and using it while out on the bike easier.

The instructions for each will tell you how much to use, how long the fuel is usable when treated, etc. There are some consistent rules of thumb. You generally only need to stabilize fuel if you won’t use it all up within two months (but carbureted bikes should still be run every couple of weeks as described above). Adding a little new gas or stabilizer to old gas won’t renew it, nor will adding more stabilizer to old stabilized gas extend its usable life. Overdosing is not an issue (unless you drink it, duh), and in my experience none of them will cure a plugged-up carb no matter how much you add to the fuel. Your best bet is to avoid plugging it in the first place.

Good luck, and please write me with any questions, comments or dissimilar experiences! rider@ridermagazine.com

I do enjoy your magazine

You have mentioned the Ethanol treatments listed above

One that I have been using for a few years with no problems is Sta-Bil 360 Marine

The 8 oz bottle treats up to 80 gallons

Its been used in my 94 Goldwing

1990 Troybilt tiller and my John deere mower

Every spring they all start fine and its less then 10 dallors at the store

Thank you and keep it coming

I am a power equipment repair tech. and 75% of the problems are fuel related. Adding more fuel stabilizer than what is called for can create what looks like frog eggs in carb.bowls that desolve when air gets to it.

2 strokes never have a corrosion problem because if the fuel evaporates you are left with a coating of oil.

So because of this I use a 50/50 mixture of stabilizer and Marvel Mystery Oil in all my power equipment and my Motorcycle ( VTX1300 ) and have never had a problem.

Do you add this mixture every fill-up, or only for winter storage?

I’m fortunate enough to live near a gas station that sells ethanol free gas. I use it exclusively in my motorcycles, lawn mower, snowblower and any other small gas engine powered equipment. I also use Stabil and Marvel Mystery oil in the fuel as well and haven’t disassembled a carburetor in years.

My 70’s Kawasakis run fine on E10 now that I have replaced the rubber fuel lines and some o-rings. I turn the petcock off when I get into the subdivision and let the carbs run dry. It didn’t take much practice to fine out when to turn off the gas so that it runs dry as I pull into the driveway.

Hey Everyone–

Here’s another way to combat this ethanol issue–

Shut off the fuel to the carburetor after each engine start use– Yup, install a manual fuel shut off valve, and shut the fuel off every time you shut ‘er down— Then you’ll have easy, “hot engine restarts”

Here’s some pic’s of what I did—

oop’s — I can’t post the pics’ I have ready to go–

The advice still stands—

If you can send me an email, I’ll send you the 5 pics I have, on how to whip this problem—

Maybe a moderator can give me permission to show these pics and ever one can benefit from my modification to my lawn tractor.

I now, can stay in the seat and operate the fuel shut off valve while moving or stopped— hooray—

There is a typo in the article, its pure-gas.org, not .com

I burn Shell premium in everything, it states no ethonal (91 octane) at the pump.

Anthony B. Mobile mechanic ASEP JASO…Only Startron works for E10-15 gas problems…Just increase doses by 50,% if needed..Anything over E-20 plus. …no possibilities….

Not mentioned, but E0 has no oxygen atoms in it, like ethanol, MTBE, & ETBE have, therefore those with carburetors will have their AFR and combustion temperatures change when switching between E0 & E10. That’s a simple mathematical fact. On the same jetting, E0 will always richen the mixture, because it has no oxygen atoms to contribute to combustion. Another reason this is important, is how it relates to those at elevation. An engine designed (jetted) for sea-level operation on E10 is typically jetted for most reliable operation on E10, which would mean an AFR of 12/2:1 – 14.1:1. This isn’t complicated, but E0 runs about 1.0 on the AFR gauge richer than E10, with its range of 12.6:1 – 14.7:1. Depending on jetting, an E10 jetted engine that you put E0 into may gain or lose power, but will always lose efficiency running E0. Add elevation (taking away atmospheric oxygen volume) to the equation and you can quickly see how running oxygen-free E0 can really adversely effect both power and efficiency on any (fixed fuel flow) carbureted engine.

The good news is, it’s not always a lose-lose proposition for E0 proponents. You just have to rejet to take advantage of E0’s oxygen-free properties. I recommend a Universal Exhaust Gas Oxygen sensor/gauge like I have on several of my carbureted engines, so you too can see your engine’s exhaust AFR, just like computer control fuel-injection engines do. The caveat to changing jetting however, is if you tune your carbureted engine for best tank range/fuel efficiency on E0, i.e. 14.7:1, beware. For one, your cylinder head temperatures will increase over those you saw running E10 (and carbureted engines don’t have knock senors to retard ignition timing, like most EFI engines do). And doing so, then replacing all the tank’s fuel with E10 will make your AFR around 15.6:1, which could damage your carbureted engine. Remember E10 is stoich at 14.1:1.

I use rec fuel in my snowmobiles. For a reason. Non enthenal.

Ethanol is almost the same ph and acidity as gas. The corrosion issue comes up when you’re fuel system has a leak that allows water to be pulled from the air. So as long as you’re fuel system is sealed you will have no issues. If you’re engine is carbrated you can adjust your jets and advance or retard your timing depending on your specific requirements. The first cars including the model T were designed to run on Ethanol that you got from your local farms before petro stations were everywhere. Just a 10 percent mix reduces your exhaust emission particulates 40 percent. Leaving any fuel in your stored engine messes everything up Ethanol or not. Always drain your fuel system and you will never have a problem.

thank you for the article